Welcome to our state-of-the-art injection molding facility, where we specialize in delivering high-quality molded products for various industries. With injection machines ranging from 25 tons to 150 tons, we handle a wide range of materials including PVC, ABS, PP, EVA, PE, and more. Our expertise spans across the shoe industry, as well as applications in electrical, automotive, and other sectors. We are committed to precision, efficiency, and innovation, ensuring that each product meets the highest standards of quality and performance.

Capabilities

Delivering Precision, Innovation, and Sustainability in Every Project.

High-Quality, Efficient Sheet Metal Manufacturing Services

OUR WORK

Gallery

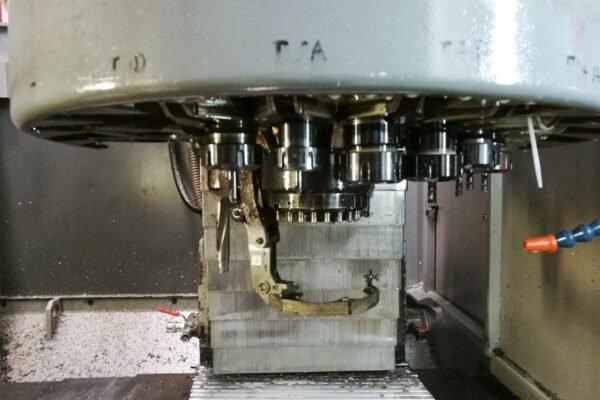

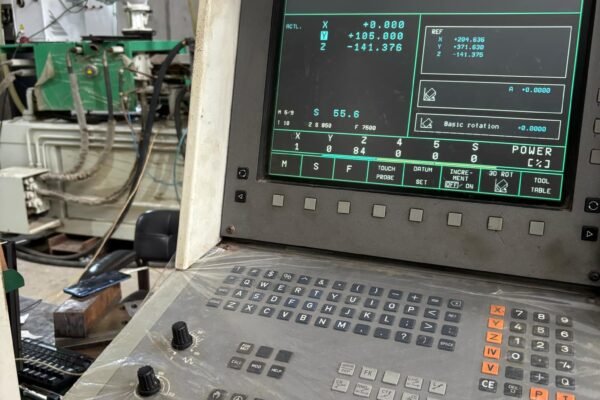

Retrofitting a Chiron FZ18S (2000) CNC Machining Center

As part of our ongoing effort to bring high-quality secondhand machines back to life, we recently completed the full retrofitting of a Chiron FZ18S CNC machining center, originally manufactured in the year 2000. Chiron is well known for its precision, speed, and reliability — and our goal was to restore and modernize this machine to meet today’s industrial standards.

The retrofitting process involved a thorough mechanical overhaul, including realignment of axes, replacement of worn ball screws and bearings, and refurbishment of the tool changer and spindle system. Electrically, we replaced the outdated CNC controller with a modern, user-friendly interface and upgraded all critical wiring, drives, and safety systems to improve stability and performance.

Post-retrofit, the machine now offers enhanced precision, smoother operation, and increased reliability, ready to take on high-speed, high-accuracy machining tasks once again. The upgraded FZ18S is now successfully running in a production facility in Egypt, proving that even two-decade-old machines can still deliver exceptional value with the right expertise.

This project highlights our commitment to giving robust German machines a second life, combining engineering know-how with sustainable practices to support manufacturers in cost-sensitive markets.

OUR WORK

Gallery

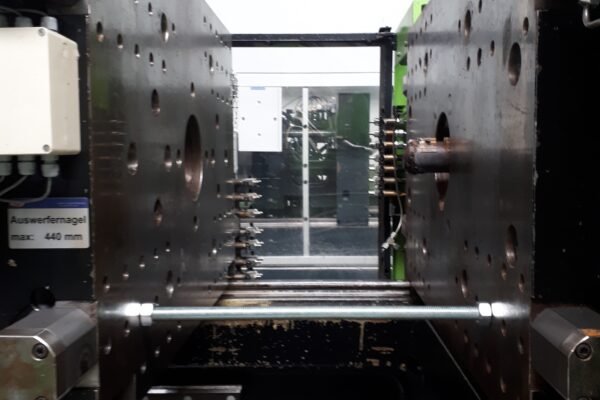

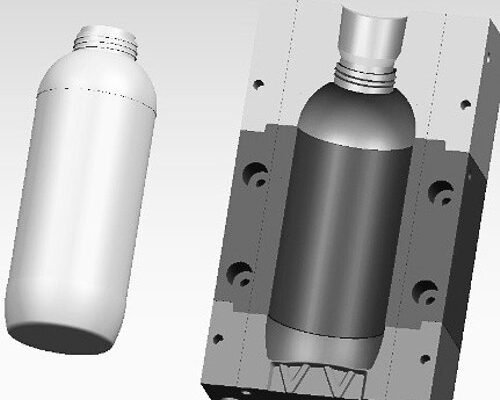

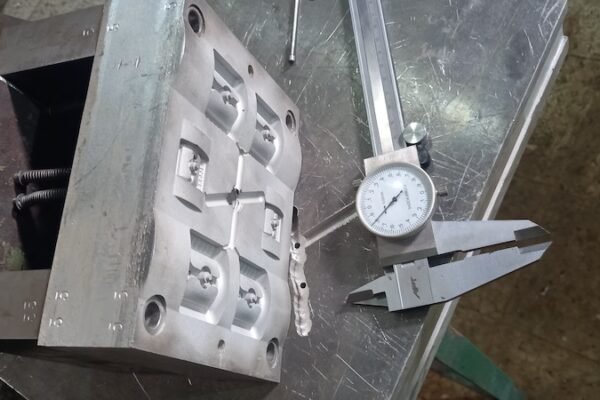

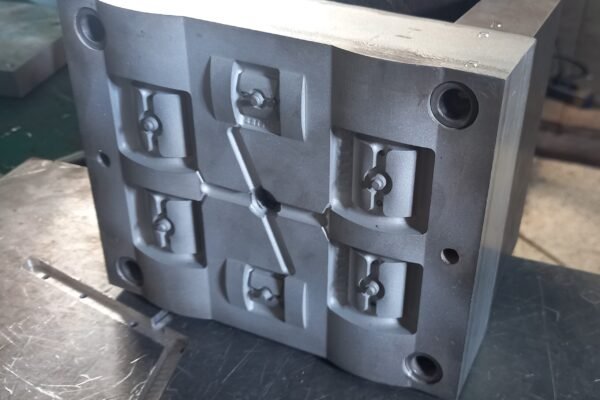

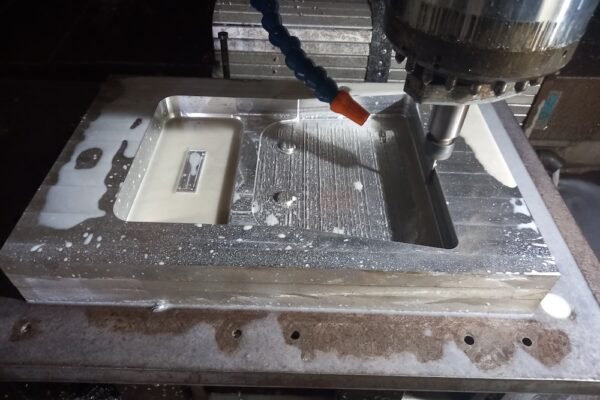

CNC Mould and Machining Center

Our CNC Mould and Machining Center is equipped with advanced German CNC machines, ensuring precision and efficiency in every project. We specialize in producing high-quality molds for injection machines up to 150 tons, serving a variety of industries. Our biggest sector is the plastic shoe industry, where we create durable and precise molds for footwear production. Additionally, we provide expert services for electrical components, automotive metal spare parts, and blow molds for beverage bottles. With cutting-edge technology and a commitment to excellence, we deliver top-notch solutions tailored to meet the unique needs of each industry.

OUR WORK

Gallery

Italian PU Casting technology is a game-changer for the shoe industry

Our Italian PU Casting technology is a game-changer for the shoe industry, providing advanced solutions for the production of polyurethane footwear components. Equipped with cutting-edge Italian machinery, we deliver high-quality, durable, and precise castings for various shoe applications. This technology allows us to produce flexible and lightweight parts, offering superior comfort and performance. With a focus on innovation and craftsmanship, our PU casting process ensures that each product meets the highest standards, helping our clients in the footwear industry stay ahead of the competition. Whether it’s for soles, heels, or other shoe components, our Italian PU casting machines deliver exceptional results every time

OUR WORK

Gallery

Linear Injection EVA Technology

Precision-molded using advanced Linear Injection technology, this EVA material ensures superior comfort, durability, and lightweight performance — ideal for high-impact use in footwear and sports gear.

OUR WORK